You need to choose options for product.

Sale

-

files/biz-vsi-330f-tc-400_0.webp

files/biz-vsi-330f-tc-400_0.webp

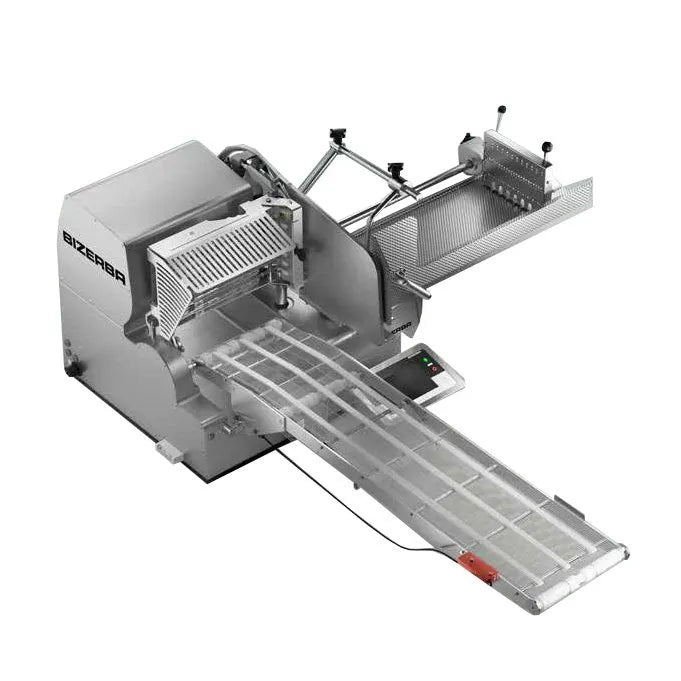

The Bizerba VSI 330F TC-400 Vertical Slicing System is an ultra-high-throughput automatic solution engineered for commercial meat-processing lines, large deli kitchens, and food-service operations requiring continuous, precision slicing with minimal manual intervention. Featuring a 13″ Grooved Vacuum Release Blade (chromium-coated hard alloy, 60–62 HRC), this system is optimized for both meats and cheeses, delivering low-friction slicing, consistent yields, and clean presentation quality.

Built for production-scale performance, the VSI 330F TC-400 incorporates an automatic vertical carriage feed, a 5-portion stainless steel mesh belt conveyor, advanced digital controls with a touch interface, and an energy-saving Emotion™ intelligent drive motor capable of up to 80 strokes per minute. With a product carriage length of 15.75″ (400 mm), stacking up to 3.5″ (90 mm), a slice-thickness range from 0.01″ to 0.50″, and a fully hose-down-capable IPx5-rated housing, this system is designed for continuous duty and high standards of sanitation.

Production-rated, cheese-and-meat capable, and built for rigorous commercial use — the Bizerba VSI 330F TC-400 delivers maximum efficiency and slicing precision for demanding food-service operations.

🔹 Key Features

-

13″ Grooved Vacuum Release Blade — optimized for cheese and meats with low-friction slicing and reduced sticking

-

Digital slicing control with configurable touch display and Emotion™ intelligent drive motor

-

Vertical feed carriage (15.75″ product length) and 3.5″ stack height (90 mm) for high-volume stacking, shaves, and circular cuts

-

5-portion stainless-steel mesh belt conveyor for batch production and portion segregation

-

Heavy-duty stainless-steel and aluminum housing with IPx5 rating and hose-down sanitation capability

-

Ideal for deli production lines, packaging prep, large kitchens, and commercial slicing operations

⚙️ Specifications

| Feature | Detail |

|---|---|

| Model | VSI 330F TC-400 |

| Blade | 13″ Grooved Vacuum Release Blade (chromium-coated hard alloy, 60–62 HRC) |

| Drive Motor | Emotion™ intelligent drive motor |

| Max Strokes/Minute | Up to 80 strokes per minute |

| Slice Thickness Range | 0.01″ – 0.50″ |

| Max Product Length (Carriage) | 15.75″ (400 mm) |

| Max Stack Height | 3.5″ (90 mm) |

| Slicer Usage | Production / Automatic Vertical-Feed |

| Slices Cheese | Yes — cheese-optimized blade (factory rated) |

| Operation | Automatic vertical feed with 5-portion conveyor |

| Installation Type | Floor-standing / integrated line system |

| Power Type | Electric |

| Electrical | 120V / 60 Hz / 1-Phase (5.8 Amps) |

| Dimensions | 53.3″ W × 70.5″ D × 52.4″ H |

| Shipping Weight | 428 lb |

| Construction | Stainless steel & aluminum housing, IPx5-rated |

| Belt / Conveyor | 5-portion stainless steel mesh belt |

| Ideal For | Large delis, meat-processing lines, sandwich prep, packaging operations |

Bizerba

Bizerba VSI 330F TC-400 | 13" Blade Automatic Meat Slicer w/ 5-Portion Conveyor

- Regular price

- $57,656.25

- Sale price

- $46,125.00

Sale

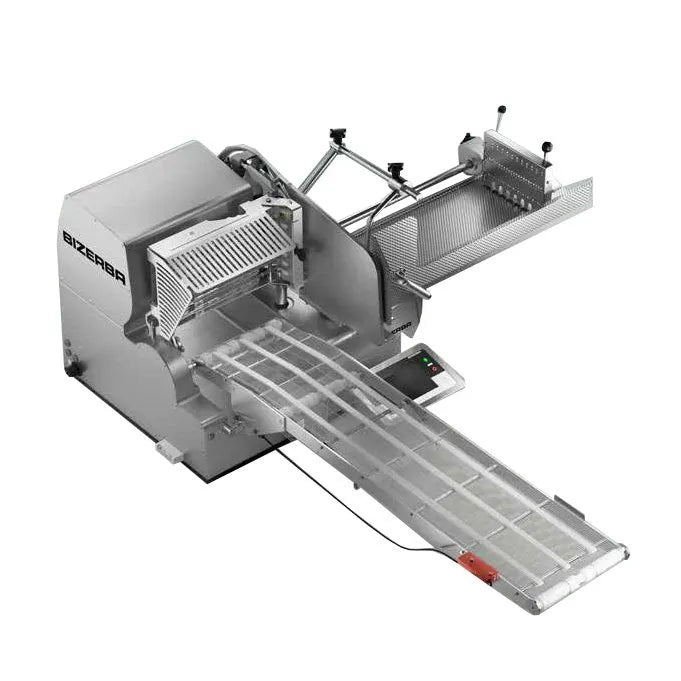

The Bizerba VSI 330F TC-400 Vertical Slicing System is an ultra-high-throughput automatic solution engineered for commercial meat-processing lines, large deli kitchens, and food-service operations requiring continuous, precision slicing with minimal manual intervention. Featuring a 13″ Grooved Vacuum Release Blade (chromium-coated hard alloy, 60–62 HRC), this system is optimized for both meats and cheeses, delivering low-friction slicing, consistent yields, and clean presentation quality.

Built for production-scale performance, the VSI 330F TC-400 incorporates an automatic vertical carriage feed, a 5-portion stainless steel mesh belt conveyor, advanced digital controls with a touch interface, and an energy-saving Emotion™ intelligent drive motor capable of up to 80 strokes per minute. With a product carriage length of 15.75″ (400 mm), stacking up to 3.5″ (90 mm), a slice-thickness range from 0.01″ to 0.50″, and a fully hose-down-capable IPx5-rated housing, this system is designed for continuous duty and high standards of sanitation.

Production-rated, cheese-and-meat capable, and built for rigorous commercial use — the Bizerba VSI 330F TC-400 delivers maximum efficiency and slicing precision for demanding food-service operations.

🔹 Key Features

-

13″ Grooved Vacuum Release Blade — optimized for cheese and meats with low-friction slicing and reduced sticking

-

Digital slicing control with configurable touch display and Emotion™ intelligent drive motor

-

Vertical feed carriage (15.75″ product length) and 3.5″ stack height (90 mm) for high-volume stacking, shaves, and circular cuts

-

5-portion stainless-steel mesh belt conveyor for batch production and portion segregation

-

Heavy-duty stainless-steel and aluminum housing with IPx5 rating and hose-down sanitation capability

-

Ideal for deli production lines, packaging prep, large kitchens, and commercial slicing operations

⚙️ Specifications

| Feature | Detail |

|---|---|

| Model | VSI 330F TC-400 |

| Blade | 13″ Grooved Vacuum Release Blade (chromium-coated hard alloy, 60–62 HRC) |

| Drive Motor | Emotion™ intelligent drive motor |

| Max Strokes/Minute | Up to 80 strokes per minute |

| Slice Thickness Range | 0.01″ – 0.50″ |

| Max Product Length (Carriage) | 15.75″ (400 mm) |

| Max Stack Height | 3.5″ (90 mm) |

| Slicer Usage | Production / Automatic Vertical-Feed |

| Slices Cheese | Yes — cheese-optimized blade (factory rated) |

| Operation | Automatic vertical feed with 5-portion conveyor |

| Installation Type | Floor-standing / integrated line system |

| Power Type | Electric |

| Electrical | 120V / 60 Hz / 1-Phase (5.8 Amps) |

| Dimensions | 53.3″ W × 70.5″ D × 52.4″ H |

| Shipping Weight | 428 lb |

| Construction | Stainless steel & aluminum housing, IPx5-rated |

| Belt / Conveyor | 5-portion stainless steel mesh belt |

| Ideal For | Large delis, meat-processing lines, sandwich prep, packaging operations |

- Regular price

- $57,656.25

- Sale price

- $46,125.00

Sale

Couldn't load pickup availability

Estimated shipping time

Estimated shipping time

You can typically expect your items to arrive within 4–7 business days, depending on your location and product availability.

What is your Return Policy?

What is your Return Policy?

At Elite Venue Essentials, we want every customer to shop with confidence. If something doesn’t go as planned, we’ve made returns and refunds simple and fair. Here’s how it works:

1. Return Window

You can request a return within 30 days of receiving your order. Unfortunately, we’re unable to accept returns after that time frame.

2. Who Pays for Return Shipping?

- If your item arrives damaged, defective, or incorrect, we’ll cover the return shipping cost.

- If you’re returning an item because you changed your mind, you’ll be responsible for return shipping fees.

3. Damaged or Defective Items

Received something broken or not working properly? Contact us within 30 days. We’ll provide a prepaid return label and once the item is returned and inspected, we’ll issue either a full refund or a replacement—including any original shipping costs.

4. Changed Your Mind?

If you no longer want the item, you can return it within 30 days—as long as it's unused, in its original packaging, and in resellable condition. You’ll need to handle the return shipping, and once we receive and inspect it, we’ll refund the product cost (excluding shipping).

5. Refund Processing

Once we receive and approve your return, we’ll send a confirmation email and issue a refund to your original payment method within 7 business days. Please allow additional time for banks or credit card companies to process and reflect the refund.

If it’s been over 10 business days since your refund was approved and you still don’t see it, contact us at support@elitevenueessentials.com and we’ll look into it immediately.

6. Restocking Fees

In some cases, a restocking fee may apply depending on the item and return reason. If applicable, we’ll clearly communicate this during your return request process.

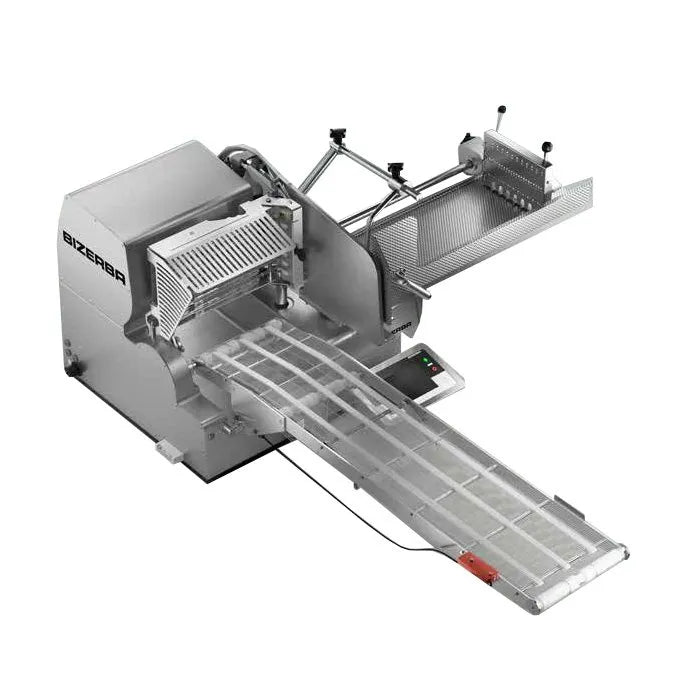

The Bizerba VSI 330F TC-400 Vertical Slicing System is an ultra-high-throughput automatic solution engineered for commercial meat-processing lines, large deli kitchens, and food-service operations requiring continuous, precision slicing with minimal manual intervention. Featuring a 13″ Grooved Vacuum Release Blade (chromium-coated hard alloy, 60–62 HRC), this system is optimized for both meats and cheeses, delivering low-friction slicing, consistent yields, and clean presentation quality.

Built for production-scale performance, the VSI 330F TC-400 incorporates an automatic vertical carriage feed, a 5-portion stainless steel mesh belt conveyor, advanced digital controls with a touch interface, and an energy-saving Emotion™ intelligent drive motor capable of up to 80 strokes per minute. With a product carriage length of 15.75″ (400 mm), stacking up to 3.5″ (90 mm), a slice-thickness range from 0.01″ to 0.50″, and a fully hose-down-capable IPx5-rated housing, this system is designed for continuous duty and high standards of sanitation.

Production-rated, cheese-and-meat capable, and built for rigorous commercial use — the Bizerba VSI 330F TC-400 delivers maximum efficiency and slicing precision for demanding food-service operations.

🔹 Key Features

-

13″ Grooved Vacuum Release Blade — optimized for cheese and meats with low-friction slicing and reduced sticking

-

Digital slicing control with configurable touch display and Emotion™ intelligent drive motor

-

Vertical feed carriage (15.75″ product length) and 3.5″ stack height (90 mm) for high-volume stacking, shaves, and circular cuts

-

5-portion stainless-steel mesh belt conveyor for batch production and portion segregation

-

Heavy-duty stainless-steel and aluminum housing with IPx5 rating and hose-down sanitation capability

-

Ideal for deli production lines, packaging prep, large kitchens, and commercial slicing operations

⚙️ Specifications

| Feature | Detail |

|---|---|

| Model | VSI 330F TC-400 |

| Blade | 13″ Grooved Vacuum Release Blade (chromium-coated hard alloy, 60–62 HRC) |

| Drive Motor | Emotion™ intelligent drive motor |

| Max Strokes/Minute | Up to 80 strokes per minute |

| Slice Thickness Range | 0.01″ – 0.50″ |

| Max Product Length (Carriage) | 15.75″ (400 mm) |

| Max Stack Height | 3.5″ (90 mm) |

| Slicer Usage | Production / Automatic Vertical-Feed |

| Slices Cheese | Yes — cheese-optimized blade (factory rated) |

| Operation | Automatic vertical feed with 5-portion conveyor |

| Installation Type | Floor-standing / integrated line system |

| Power Type | Electric |

| Electrical | 120V / 60 Hz / 1-Phase (5.8 Amps) |

| Dimensions | 53.3″ W × 70.5″ D × 52.4″ H |

| Shipping Weight | 428 lb |

| Construction | Stainless steel & aluminum housing, IPx5-rated |

| Belt / Conveyor | 5-portion stainless steel mesh belt |

| Ideal For | Large delis, meat-processing lines, sandwich prep, packaging operations |

-

FREE SHIPPING IN USA

Free shipping with every order

-

SATISFACTION GUARANTEED

If your order arrives defective or fails

to function properly, you will receive a full 100% refund!

-

PREMIUM CUSTOMER SUPPORT

Connect with us through live chat, email,

or phone, and we will address any questions you may have!

-

SECURE ENCRYPTED PAYMENTS

We utilize advanced encryption to

ensure there is never an issue with your privacy.